After many delays, my sandblaster is finally done, and it works great. :rock:

The structure of mine is elusively wood; I didn't use any metal to cover the inside.

I'm not gonna tell you how to actually build the box, if you need help with that part then you shouldn't be working on a motorcycle.

I didn't draw out a plan of any kind, I just started cutting plywood, and designed it as I went.

Early phase, basically just a box:

![Image]()

![Image]()

Here I enclosed the bottom:

![Image]()

Once the bottom was enclosed, I made pieces for the inside that made it taper in both directions, as you see here:

![Image]()

![Image]()

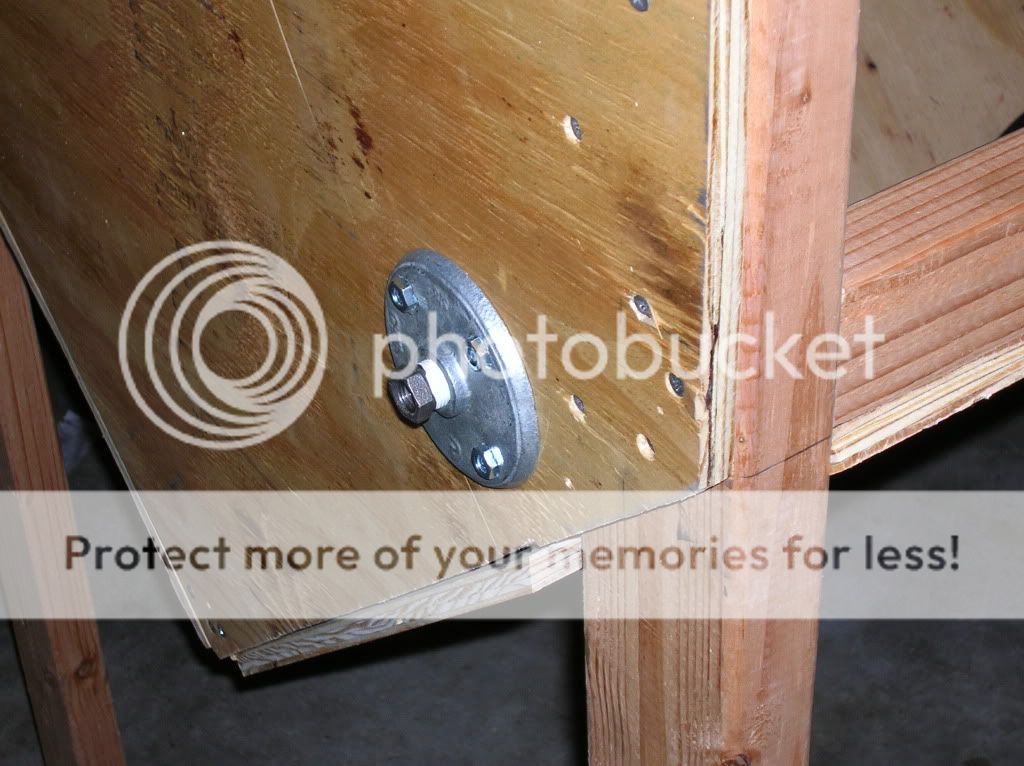

Found some fittings to run the air hose through the plywood wall. I think they are plumbing fittings though.

![Image]()

![Image]()

I installed the hoses for air and the sand pickup. I bought a super cheap blasting gun off fleabay, it works great, and came with the pickup hose, pickup pipe, and some spare nozzles.

![Image]()

Added a light so I can see:

![Image]()

At this point it started to get kinda heavy, so I added some wheels. Do not underestimate the value of this feature.

![Image]()

Then I put my door on. I used regular home door hinges, very sturdy, and cheap. Home depot sold acrylic sheets in 30"x30" for like $17, so I bought one and cut it in half, that way I have a spare for when the glass gets shitty. I cut the hole a little smaller than the glass, and made little wood retainers on three sides to hold the glass in, then I just used some race tape around the edges, and viola! :rock:

![Image]()

I put foam weather stripping around the edges to seal it, and used these style of latches, I dont remember what they're called but you get the idea.

![Image]()

I put a pvc fitting in the side near the light so I could hook my shopvac up to it. The vacuum fits in great, but I need to add some vents on the other side, it sucks to hard right now that you can't move your hands with the vacuum on.

![Image]()

Completed, ready for operation:

![Image]()

My local place didn't have any alum oxide, so I got impatient and went with glass beads. A little softer, but works great.

![Image]()

Overall this was a great idea and saved me a ton of money.

I spent about $90 on wood, $20 on the gun, $20 on the media, $20 on hardware, $17 on hose & fittings, $15 on glue and screws. I'm not sure how much I spent total, maybe $250, but I think to buy a unit this large would be $1000 or more.

It should be large enough to do my frame if need be. It will def fit, but I'm not sure if I'll have the mobility to actually do a good job.

The structure of mine is elusively wood; I didn't use any metal to cover the inside.

I'm not gonna tell you how to actually build the box, if you need help with that part then you shouldn't be working on a motorcycle.

I didn't draw out a plan of any kind, I just started cutting plywood, and designed it as I went.

Early phase, basically just a box:

Here I enclosed the bottom:

Once the bottom was enclosed, I made pieces for the inside that made it taper in both directions, as you see here:

Found some fittings to run the air hose through the plywood wall. I think they are plumbing fittings though.

I installed the hoses for air and the sand pickup. I bought a super cheap blasting gun off fleabay, it works great, and came with the pickup hose, pickup pipe, and some spare nozzles.

Added a light so I can see:

At this point it started to get kinda heavy, so I added some wheels. Do not underestimate the value of this feature.

Then I put my door on. I used regular home door hinges, very sturdy, and cheap. Home depot sold acrylic sheets in 30"x30" for like $17, so I bought one and cut it in half, that way I have a spare for when the glass gets shitty. I cut the hole a little smaller than the glass, and made little wood retainers on three sides to hold the glass in, then I just used some race tape around the edges, and viola! :rock:

I put foam weather stripping around the edges to seal it, and used these style of latches, I dont remember what they're called but you get the idea.

I put a pvc fitting in the side near the light so I could hook my shopvac up to it. The vacuum fits in great, but I need to add some vents on the other side, it sucks to hard right now that you can't move your hands with the vacuum on.

Completed, ready for operation:

My local place didn't have any alum oxide, so I got impatient and went with glass beads. A little softer, but works great.

Overall this was a great idea and saved me a ton of money.

I spent about $90 on wood, $20 on the gun, $20 on the media, $20 on hardware, $17 on hose & fittings, $15 on glue and screws. I'm not sure how much I spent total, maybe $250, but I think to buy a unit this large would be $1000 or more.

It should be large enough to do my frame if need be. It will def fit, but I'm not sure if I'll have the mobility to actually do a good job.