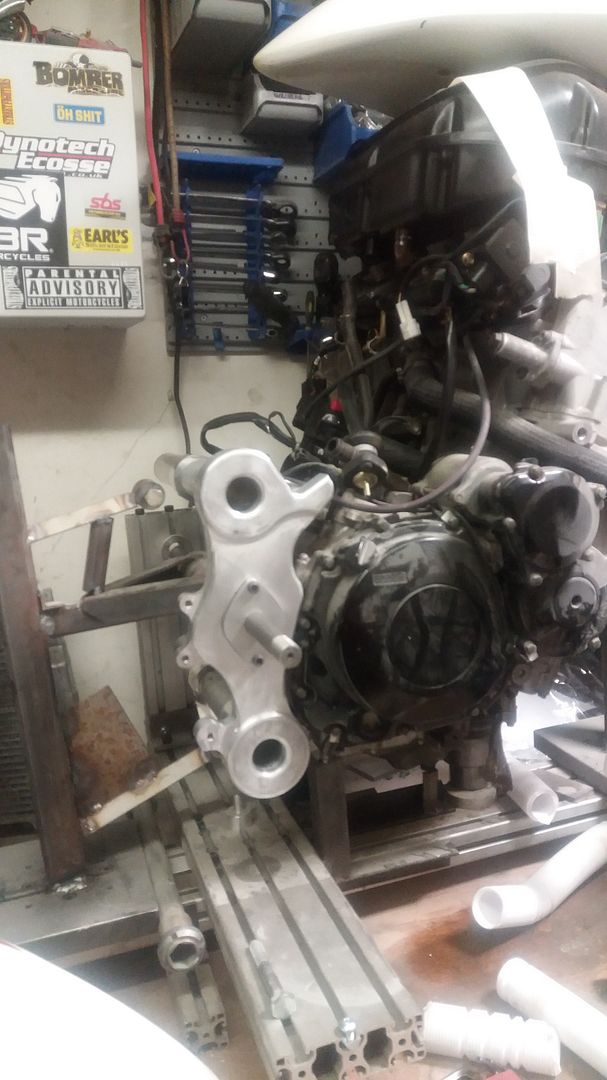

Decided 30 years ago I was going to build my own frame.... unless immortality kicks in soon I better get my finger out

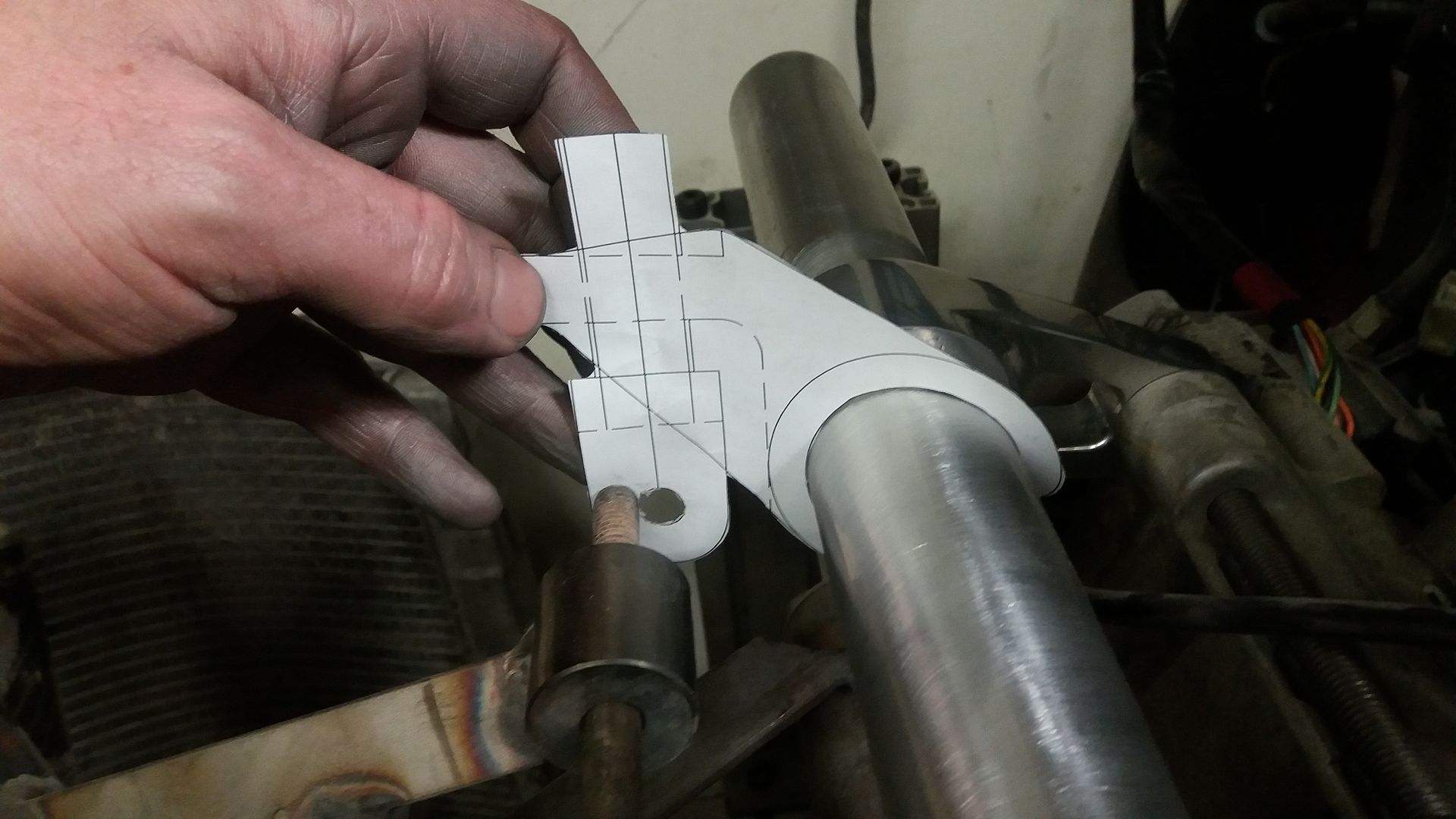

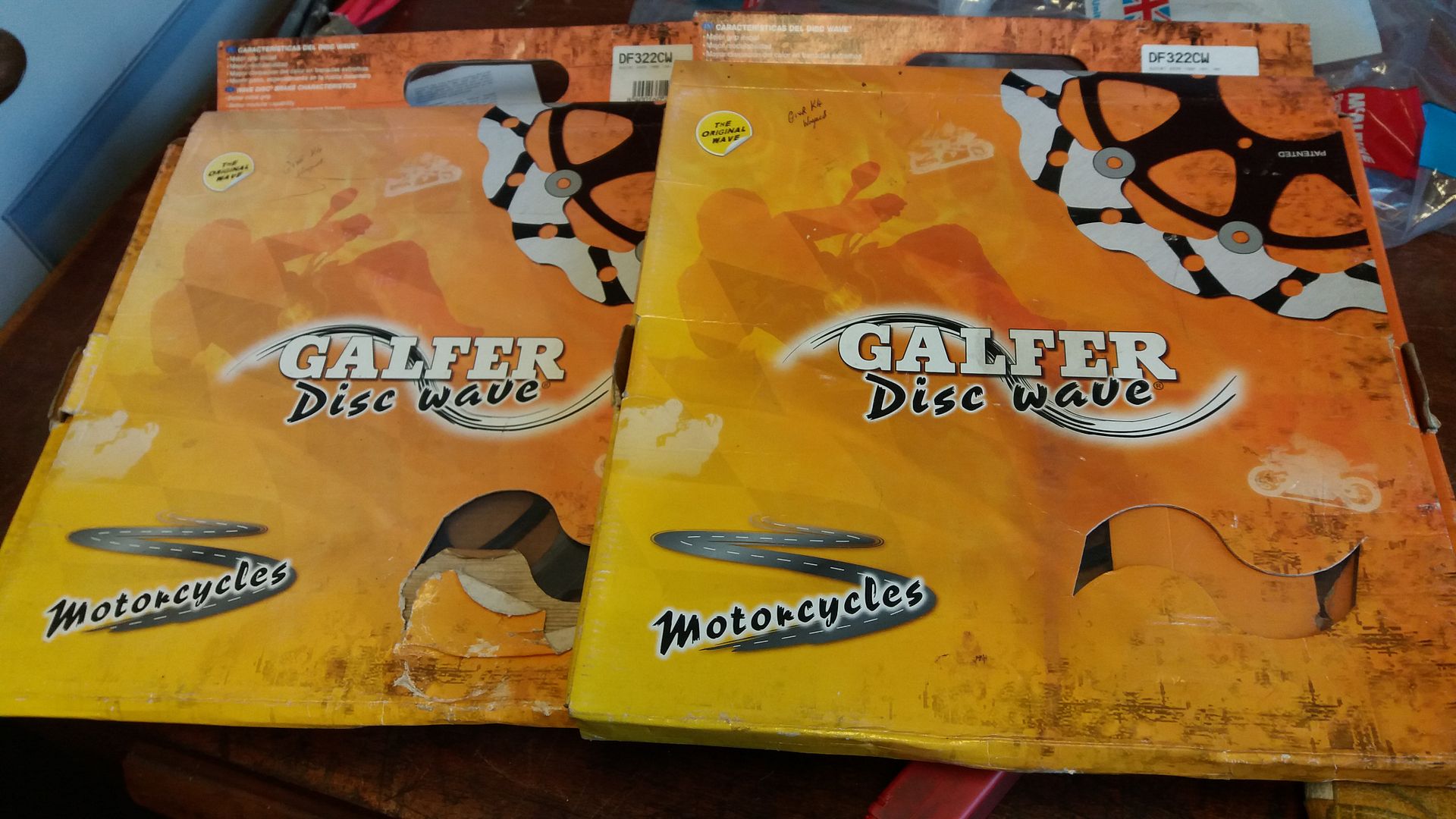

A friend was selling this for a good price

so after a long day of driving

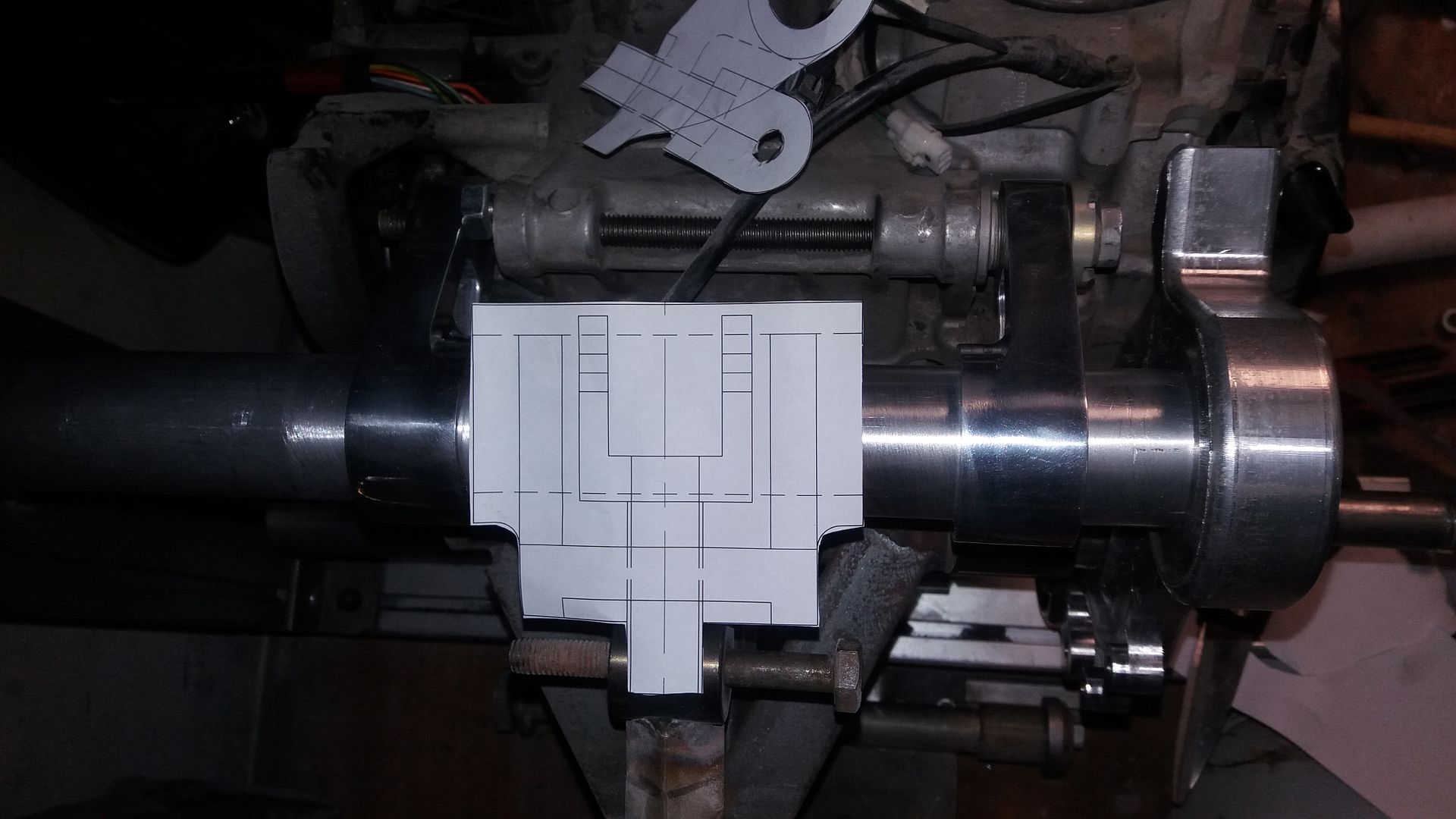

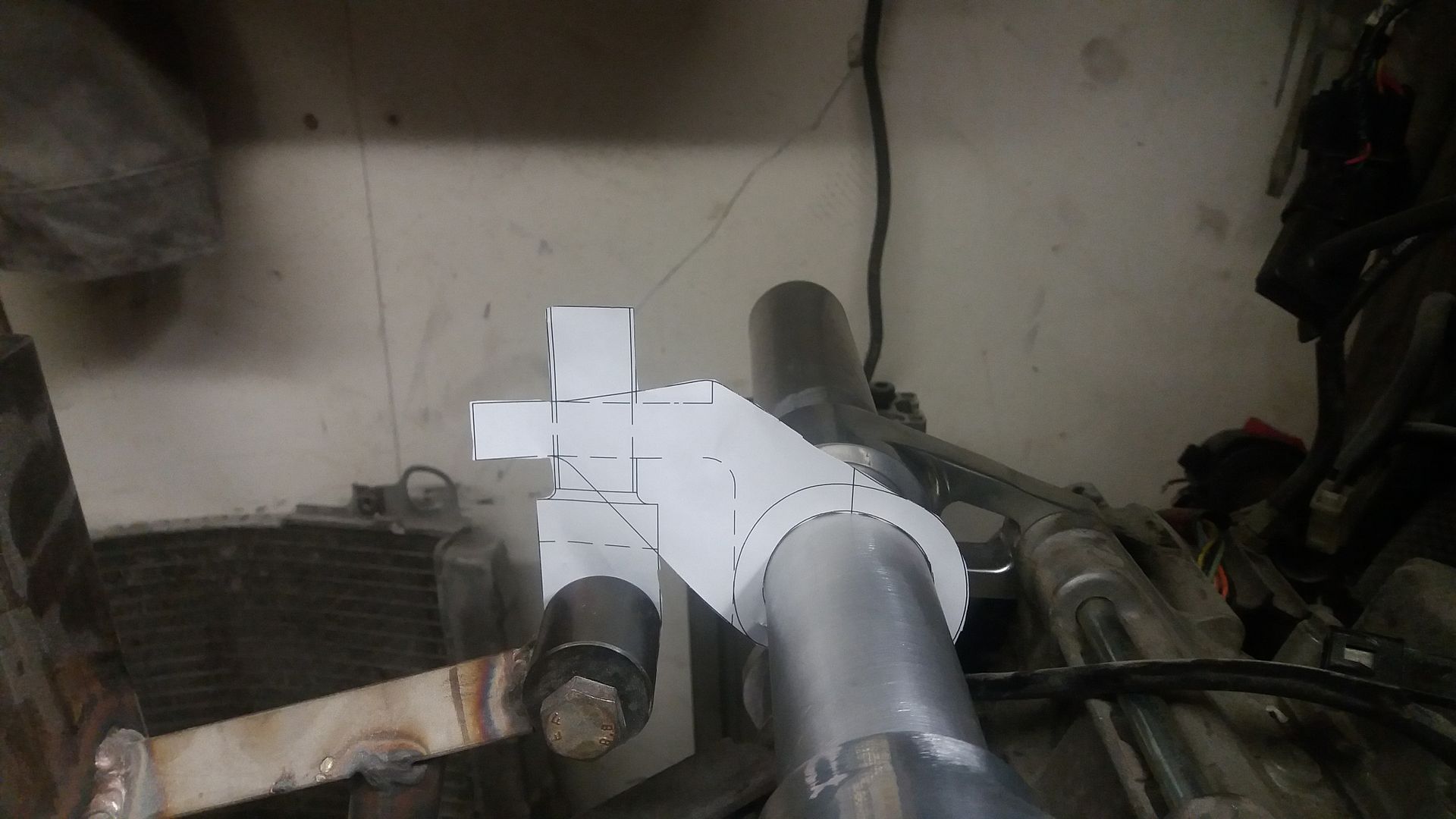

So now that the Bandikat is put to bed I reckon the time is now

this will be a long term thang, to be honest the full frame thing is a little daunting,

in for a penny tho

A friend was selling this for a good price

so after a long day of driving

So now that the Bandikat is put to bed I reckon the time is now

this will be a long term thang, to be honest the full frame thing is a little daunting,

in for a penny tho